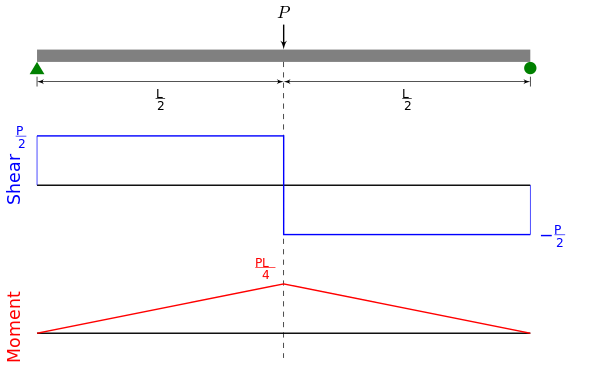

Teaching engineering often involves using pictures. These pictures could depict the mechanics of some physical phenomena with a sketch, describe the relationship between different parameters with a graph or illustrate the interactions between components of a complex system with a diagram. If you imagine how you would explain any of the classic concepts of engineering science, things like bending moments in a beam, the development of a fluid boundary layer or the voltage and current in an electrical circuit, you will most likely include sketching schematic pictures to represent these systems as part of the process.

Two dimensional representations are ubiquitous in the communications between engineers. Yet the world in which engineers apply their craft is, more often than not, three dimensional. So why is it that 2D drawings are so much more widely used to convey engineering concepts than 3D ones?

For a long time the tools available to the engineering educator, such as notebooks, printouts, drawing boards and whiteboards, have been limited to flat surfaces. Common devices used for digital methods of communication, such as monitors, mobile phones and projectors are also mostly flat surfaces. But that isn’t necessarily going to remain the case and there are indications that 3D could become the new standard in how ideas are communicated. Engineering educators need to pay attention to this.

Firstly, although most digital devices have a flat surface to display their content, they have the advantage of being able to represent 3D objects by dynamically orienting the projection of the 3D object onto the 2D screen. It is only recently that computing hardware has become powerful enough and software has been efficient enough to make the creation and manipulation of 3D content widely accessible. TinkerCAD offers the creation of 3D objects with nothing more than access to a web browser and passing 3D content between different systems is now almost a turnkey process.

Secondly, students are much more likely to consume their content through a digital device rather than anything paper based, giving wider access to the potential to display 3D objects. This has been a clear trend for a number of years now, but the Covid-19 pandemic has cemented the superiority of the digital display of teaching material compared to the printed page.

Finally, the potential future utilisation of virtual and augmented reality for all manner of common tasks cannot be ignored. While in its infancy, especially for teaching, the plummeting cost of VR hardware coupled with the noticeable investment being made by the large tech giants is an indication that this technology could become a mainstream component of how people interact.

The limitations of traditional tools to articulate visual concepts have influenced our methods for communicating, such that the use of 2D visualisation is completely ingrained in our professional lives. I was taught engineering using 2D, so my mind thinks about explaining things using 2D and so the cycle continues. But as we are now all acutely aware, disruptive technologies can change traditional industries rapidly, and those that don’t pay attention get left behind.

As with implementing any new technology, there is a cost in developing the skills required utilise the tools. To justify that investment of resources, there has to be a clear benefit. In many cases, the presentation of information in 2D will be preferable to 3D visualisation, as 2D schematics can be used to make complex systems straightforward to understand without the burden of having to manipulate the image to look around it. There are plenty of examples of the arguably unnecessary use of 3D to convey information where 2D would have worked equally well.

In the Fluids Engineering lab, we were very excited to create and share with students, in advance of their experiments, a digital 3D version of our teaching wind tunnels. This allowed them to rotate around and zoom in and out of the equipment. The idea was to provide an introduction to the apparatus so students could prepare for the lab class. The tool is very impressive. However, the ability to rotate around the equipment and zoom into and out of the 3D object isn’t enormously helpful, as students using the real equipment will typically stand in front of the fixed equipment and do not experience the other viewpoints. Manipulating the 3D object on the screen is quite fun, and there is an advantage in making an activity more engaging even if the extent of the communication of content isn’t enhanced. But if that is the justification, we should be conscious of this rather than kidding ourselves that we are adding any substantial value to the learning.

As I am particularly interested in practical engineering education, I’m aware of the increased use of 3D photography and videos to provide virtual lab tours. Just type “360 lab tour” into google and you will find a plethora of examples. But is there any educational value in providing students a tour of the lab in advance of their arrival? There is definitely a marketing opportunity to show off impressive facilities and the possibility of students being less anxious about entering an unfamiliar environment. But I question if there is much learning from knowing the relative positions of the furniture or pieces of equipment in 3D that couldn’t be achieved through simpler means, like a map. Or signs. When students come into my Fluids Engineering lab, they can usually find the piece of equipment they are looking for after a quick scan around the room, because they are aware of what it looks like from a 2D photograph they have been provided with in advance.

I’m constantly on the lookout for examples of where using 3D has a distinct advantage over other approaches. So far I have two, which I will offer here, but I’m keen to hear if people have others.

To convey a sense of scale

Engineers can work on some pretty big stuff. I can remember being taken to Drax power station as part of my undergraduate studies and being awed by the size of the various fans and pipes and other massive engineering things. When I led the programme for Energy Engineering I would always take my students to a wind farm. While you can explain that large turbines have 100 meter blades spinning at 150 miles an hour, to really sense what it feels like you need to stand underneath one. If you have never done it, I’d highly recommend it.

Obtaining a similar experience of scale and awe can be achieved using VR headsets. The sensation of being physically present isn’t quite the same, but the accessibility is unrivalled. Taking large groups of students on field trips is expensive and an organisational nightmare. Even relatively local sites will be a challenge to find the time to accommodate. But with a £300 headset students could travel to a range of different engineering facilities across the planet and once the content is created, the scalability is virtually unlimited.

When 2D schematics do not represent 3D objects

One of the more enthusiastically received experiments we do in the Fluids Engineering lab is the generation of smoke rigs. We can make small ones with custom built smoke ring generators, or giant ones with a plastic dustbin into which I cut hole in the bottom. There is something mesmerising about watching the smoke gently precess down the length of the lab, holding together with stability afforded by the vortex.

I ask students if they had ever seen anything like it before during their studies of fluid mechanics and I am surprised with how frequently the answer is that they have not. I am surprised because they definitely have, as similar structures appear as “recirculation zones” in the step where pipes expand from a smaller to larger diameter - a reasonably classic piece of fluid mechanics that all students do learn about. But after some further questioning, it occurred to me that the lack of recognition is caused by the overwhelmingly common presentation of this structure in 2D. It had compromised their understanding of the actual physical manifestation of the system.

Shown above is a slice through a circular pipe. The recirculation zones are the ovals and this is pretty much universally how they are depicted in all explanatory teaching material. But it is just a slice to allow it to be shown in 2D. In the real, 3D pipe this 2D cross section is rotated around the axis and the recirculation zones take on the shape of a doughnut, which an Engineering would call a "torus" because we are cool, and is almost identical to the structure seen in a smoke ring.

I created the 2D water flowing form a smaller to larger diameter pipe schematic shown above in 2010 using open source vector graphics tool Inkscape. I chose 2D because this is the way I had been taught about recirculation zones and because building 3D content was prohibitively out of my expertise. However, if I were to prepare this teaching material in 2022, I would consider doing it in 3D using easily accessible, simply to use and free tools. In about 60 seconds and with nothing more than a web browser, I can create a torus in TinkerCAD, download the .STL and upload it to Sketchfab to embed within a webpage.

Comments

Post a Comment