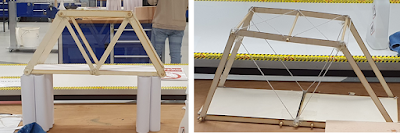

Engineers in the real world work in teams on projects to design, build and test artefacts. It is important that students, or trainee engineers, are able to effectively function when they start work and one of our roles as educators is to give students these experiences as part of their studies. The first-year Civil and Structural Engineering curriculum at Sheffield University has contained a module (CIV1200 Introduction to Civil and Structural Engineering Design) where students design, build and test wooden small-scale bridges (Figure 1) working in groups of up to 12. This provides a series of vital Learning Outcomes (i.e., Interpret a project brief, produce a design and present the results) and is important for accreditation.

|

| Figure 1: Two examples of bridges built during this year lab sessions |

Typically, the design stage of this module is supported with

lectures, tutorials and lab activities, while the making part of this module takes

place towards the end of the semester with students having access to our PUPS

(pop-up project spaces). These are cabinets on wheels filled with hand tools (Figure 2) that students

can use with minimal supervision. Historically, students have also been able to

use the iForge (our student-led Maker Space) to build their models. Finally, testing of the bridges takes place in the lab where one member of the teaching team

would carry out the load test in front of students.

|

| Figure 2: PUPS - Pop-Up Project Space |

With the strictures imposed by the current pandemic, the

amount of face‑to‑face (F2F) teaching has inevitably dropped across the

University. In addition, iForge was no longer in a position to support curricular

projects and, in general, the access to MEE laboratories has been severely

curtailed. For example, the Structures Laboratory where the bridge-building historically

took place had its capacity slashed from 80 to 20. Additionally, in line with

University H&S policy, students needed to stay 2 m apart, wear face

coverings, and working stations had to be sanitised after each use (Figure 3). This meant

that the module needed to be reconfigured to allow the key learning outcomes to

be achieved while keeping the students motivated and, hopefully, happy.

|

| Figure 3: Implementation of University and departmental H&S policies during the Bridge Building lab activity |

Changes to the design stage consisted of moving lectures and tutorials online. Pre-recorded videos of lectures were released weekly covering basic concepts of design, while a synchronous online session was used to provide feedback to students and have a pulse check about their engagement.

A major reorganisation was needed for the build and test part of the course. Three main changes were made. Firstly, the testing of the bridges was performed (as usual) by the teaching team, but here, instead of doing this in front of the students, the test was recorded (see video below) and circulated with the students along with all the relevant experimental results (i.e., total weight, peak load, geometrical dimensions).

The second change was that a limited amount of “service

build” (i.e., laser cutting) was provided. Historically, plywood laser cutting

would take place during the bridge building lab sessions. This allowed students

to quickly assess if the cut components matched what they intended to design

and, when necessary, amend their drawing and have parts cut again. However,

because of the aforementioned limitations, a new procedure resembling the

typical designer/ contractor relationship was introduced. Students (designer) created

files for their parts which were submitted ahead of time. Staff (contractor) reviewed

the files, provided feedback when necessary and manufactured the parts making

them available to students on the day of the first timetabled Bridge Building

lab session. This new procedure worked very well for the majority of groups,

however, in a few instances some problems in the submitted files (e.g., wrong size,

unintended cutting lines) were discovered only once students turned up to the

Building Session, generating some delays in the delivery of the amended parts. Also,

one of the group experienced some delays as the student responsible for the parts

drawing was working remotely in a different time zone and was not available at

the time of the first building session.

Finally, the actual build was made simulating an assembly line. One student from each group was able to access one of the PUPS at a time. They had a maximum time of 12 hours per group, with bookable slots of 1 hour. Handover between one team member and the next was achieved by the expedient of positioning a Perspex sheet across the middle of the working station so that the finishing student could communicate effectively with the new starter. Figure 4 provides an example of the working station. The finishing student, after sanitising the working station, all tools used and the bridge itself, left the space and the new one took over on the build. The service manufactured parts were incorporated into the build with the additional material provided (A4 papers, string, steel washers, wooden dowels). During the building session, students were encouraged to use digital devices to remotely connect with other group members to discuss arising problems and not to feel left alone. Throughout the activity GTAs, technical staff, and academics were available to support students and to provide feedback. These strategies were successful as most of the groups engaged well with the activity completing the bridge well ahead of time. Initial informal feedback suggests that the activity was generally well-received. It should also be pointed out that some groups lamented the limited engagement of some groups members which resulted in additional workload and pressure; others effectively managed the different tasks even when students were not in Sheffield for the semester.

Going forward, some of the elements developed to deal with the restrictions imposed by the pandemics will be, at least conceptually, retained. In particular, the designer/contractor relationship will be further exploited, and the assembly line model will be optimized to allow two students on each workstation in order to more effectively promote teamwork. Already next semester, given the successful implementation, a similar approach to building artefacts is expected to be rolled out to other modules.